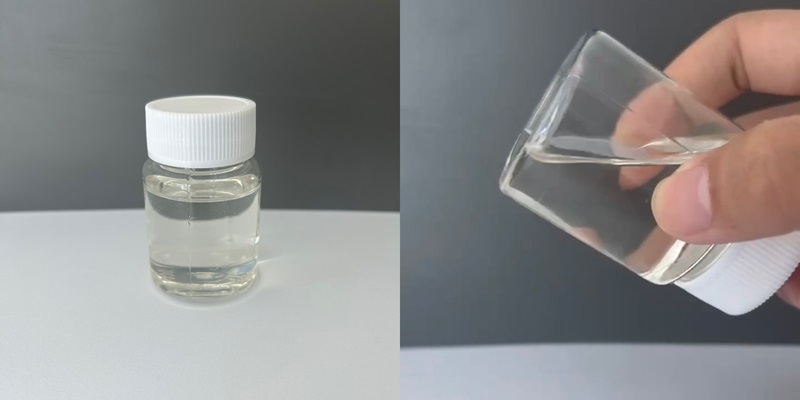

Professional grade dibutyltin dilaurate catalyst

MXC-T12 (equivalent to DABCO T12) is a highly efficient dibutyltin dilaurate catalyst designed and developed for the polyurethane industry. As a representative of metal organic compounds, MXC-T12 exhibits excellent catalytic activity in polyurethane (polyol-isocyanate) reactions, which can significantly improve the mechanical properties and production efficiency of the final product.

Core product advantages

MXC-T12 catalyst has several key advantages:

- Precise control of gel reaction: optimize the reaction kinetics of polyols and isocyanates

- Shorten the tack-free time: improve production efficiency and speed up the demoulding cycle

- Enhance the mechanical properties of foam: improve the cell structure and enhance the durability of the product

- Synergistic effect: the use with amine catalysts can greatly improve the overall reactivity

Main application areas

1. Polyurethane foam production

MXC-T12 is widely used in the manufacture of various types of polyurethane foams:

- Flexible foam: improve resilience and durability

- Rigid foam: enhance structural strength and dimensional stability

- Microcellular foam: optimize cell uniformity and density distribution

2. Two-component system

Excellent performance in the field of polyurethane adhesives and sealants:

- Precise control of curing time

- Improve the bonding strength of the final product

- Optimize the construction operation window

3. Special polyurethane products

Suitable for various special applications that require precise control of gel time:

- Elastomer products

- Paints and coatings

- Composite materials

Technical characteristics and usage recommendations

The catalytic activity and service life of MXC-T12 are affected by many factors:

1. Amine additives: The activity is significantly enhanced when used in conjunction with amine catalysts

2. Moisture content: The moisture content in the raw materials needs to be controlled

3. Storage conditions: It is recommended to store in a sealed container at 15-25°C

4. Formula compatibility: Compatible with most polyurethane raw material systems

Recommended addition amount: Usually 0.05%-0.3% of the total amount of polyols, and the specific amount needs to be adjusted according to the formula and process conditions.

Why choose our MXC-T12?

1. Quality assurance: strict production quality control, each batch of products is fully tested

2. Technical support: provide professional technical consultation and formula optimization suggestions

3. Stable supply: a complete supply chain system ensures timely delivery

4. Customized service: customized solutions can be provided according to customer’s special needs

Get professional support

Whether you need to improve the performance of existing products or develop new polyurethane formulas, our technical team can provide you with professional advice and customized solutions.

Contact our technical experts now for more product information and technical data:

- Email: info@mingxuchem.com

- Website: https://www.mingxuchem.com

Unleash the full potential of your polyurethane products by optimizing the catalyst system! MXC-T12 helps you gain a technological advantage in the competitive market.

Post time: Apr-27-2025