Introduction

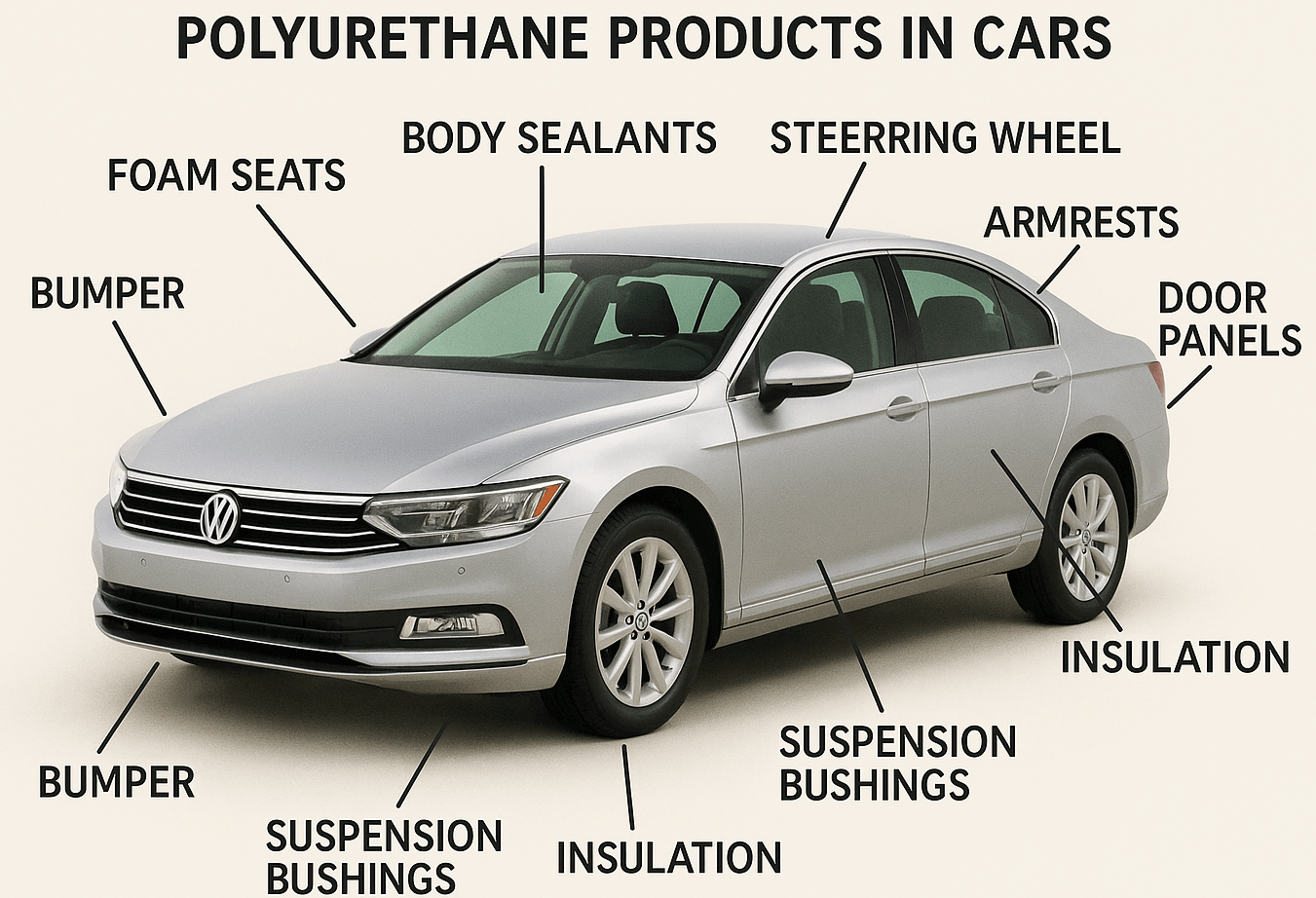

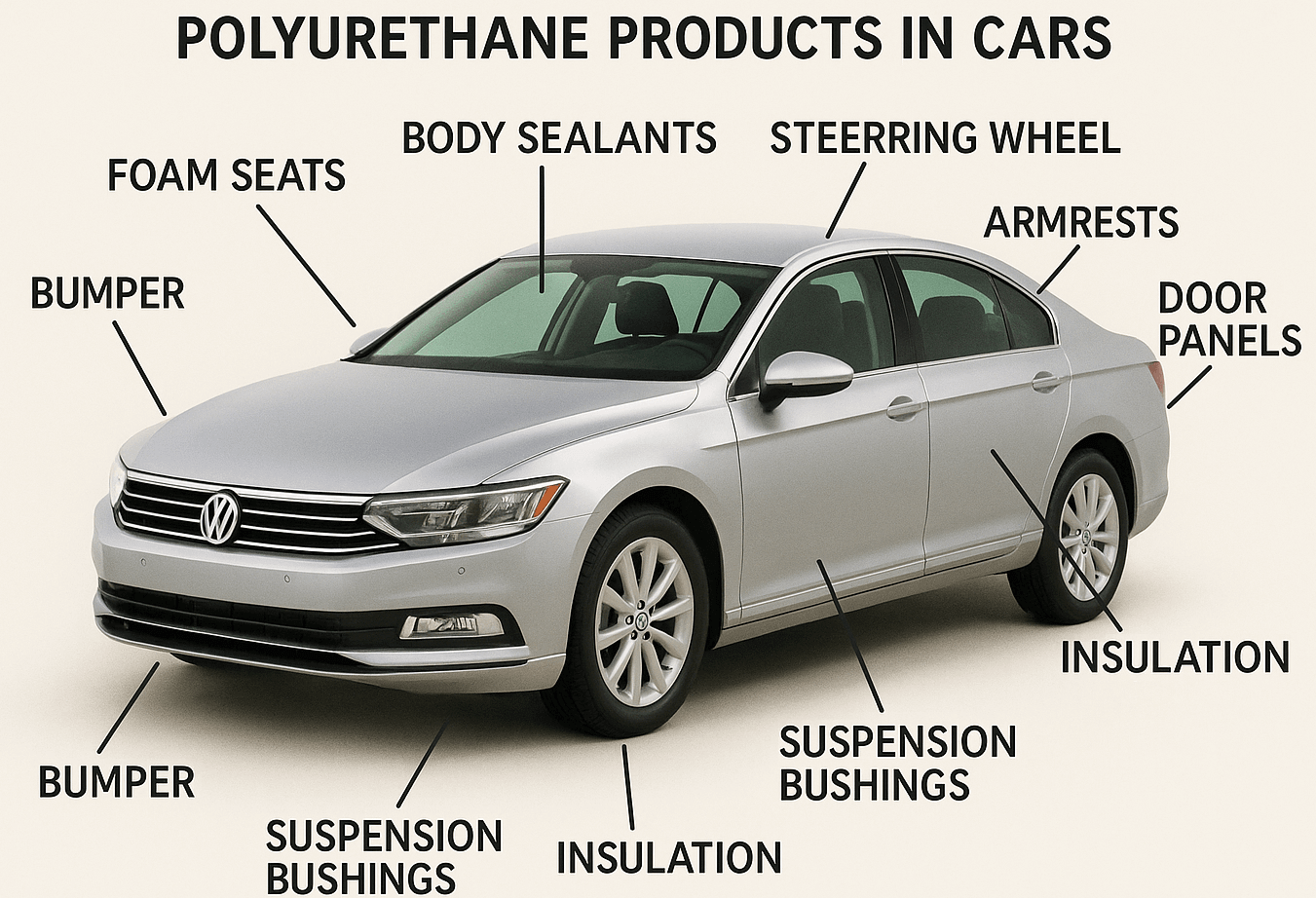

In today’s automotive industry, polyurethane (PU) materials play a crucial role in achieving lightweight design, enhancing comfort, and improving durability. From car seats and dashboards to headliners and sound insulation systems, polyurethane components are found in virtually every corner of a vehicle. Behind the superior performance of these materials lies a key chemical driver—the polyurethane catalyst. The polyurethane catalyst controls the reaction rate between isocyanates and polyols, thereby ensuring that each automotive application achieves the required mechanical and physical properties.

What Are Polyurethane Catalysts?

Polyurethane catalysts are chemical substances that accelerate the reaction between polyols and isocyanates during foam formation. Without catalysts, the polyurethane reaction rate would be too slow or uncontrollable for industrial production. By adjusting the type and amount of catalyst, manufacturers can precisely control the gelation, foaming, and curing processes to obtain foams with specific hardness, elasticity, and stability.

Two main types of polyurethane catalysts used in the automotive industry are:

Amine catalysts—primarily used to promote the foaming reaction (water-isocyanate reaction) and balance the foam’s rise curve and cell structure. For example, tertiary amine catalysts such as MXC-A1 (BDMAEE) and MXC-37 result in a smooth foam rise and uniform cell distribution.

Metal catalysts—tin-based catalysts, such as dibutyltin dilaurate (MXC-T12) and stannous octoate, accelerate the gelation reaction (polyol-isocyanate reaction), thereby speeding up curing and improving mechanical strength. In environmental systems, novel non-tin metal catalysts are increasingly being used to reduce emissions and toxicity.

Key Automotive Applications of Polyurethane Catalysts

1. Car Seats and Headrests

Flexible polyurethane foam is the most commonly used cushioning material in car seats and headrests. Catalysts such as MXC-A33 or MXC-BDMA help regulate the density and resilience of the foam, ensuring consistent comfort and durability. A balanced catalyst system provides excellent early flowability, uniform cell structure, and good compression recovery properties, used to produce ergonomic car seats.

2. Dashboards and Steering Wheels

Semi-rigid and microporous polyurethane foams are commonly used in dashboards and steering wheels. These materials must combine flexibility and dimensional stability. Catalysts such as MXC-R70 and MXC-B20 are used to control the front-end viscosity delay while ensuring strong back-end curing. This results in a smooth foam surface and excellent adhesion to the substrate, enhancing aesthetics and tactile feel.

3. NVH (Noise, Vibration, and Harshness) Control

Polyurethane foam is a highly efficient sound-absorbing and vibration-damping material, widely used in door panels, headliners, and floor insulation. Catalysts such as MXC-41 and MXC-TMA ensure precise foam molding and consistent cell structure, thereby enhancing sound and heat insulation performance.

4. Automotive Coatings and Adhesives

In the automotive coatings and adhesives field, polyurethane catalysts such as MXC-T9 and MXC-T12 accelerate crosslinking and curing reactions, thereby improving adhesion, gloss, and chemical resistance. Appropriate catalyst formulations ensure faster drying of coatings and optimal bond strength of adhesives across a range of temperature conditions.

Working Principles of Polyurethane Catalysts in Automotive Production

Polyurethane formation involves two primary chemical reactions:

Gelling Reaction: Between isocyanate and polyol, forming urethane linkages and providing strength.

Blowing Reaction: Between isocyanate and water, generating carbon dioxide to create foam.

A balanced catalytic system ensures that these two reactions occur at controlled rates. Amine catalysts promote the blowing reaction, while metal catalysts accelerate gelation. The correct combination allows the foam to expand smoothly without collapsing, while curing sufficiently to achieve high mechanical performance.

In automotive manufacturing, process parameters such as temperature, humidity, and mixing ratio are closely monitored to optimize catalyst efficiency. The goal is to achieve consistent foam properties, minimal emissions, and long-term performance stability.

Advantages of Using High-Performance Polyurethane Catalysts

Precision Control: Adjust the foaming and curing time for different automotive components.

Low Odor & Emission: Modern catalysts such as MXC-R40 and MXC-70 offer low-VOC performance suitable for eco-friendly car interiors.

Compatibility: Applicable in both HFC and HFO blowing agent systems, supporting sustainable manufacturing trends.

Improved Durability: Enhance foam resilience, adhesion, and heat resistance for extended component lifespan.

Conclusion

Polyurethane catalysts are the unsung heroes behind the comfort, safety, and durability of modern automobiles. By controlling reaction rates and foam structure, they ensure that every seat, panel, and insulation layer meets stringent automotive standards. As the industry transitions to lightweight design and green manufacturing, high-performance, low-emission polyurethane catalysts will continue to play a role in driving innovation.

Post time: Nov-05-2025