Modern sandwich panel technology and polyurethane core materials

As an important innovation in the construction industry, polyurethane sandwich panels have become the preferred material for industrial plants, cold storage, clean workshops and other buildings. This composite material consisting of two layers of metal panels and a polyurethane foam core in the middle relies heavily on a professional polyurethane catalyst system for its excellent performance. Our MXC series catalysts are specially optimized for sandwich panel production, which can significantly improve product quality and production efficiency.

Catalyst system for sandwich panels

Unique advantages of MXC-37 (DMAEE) catalyst

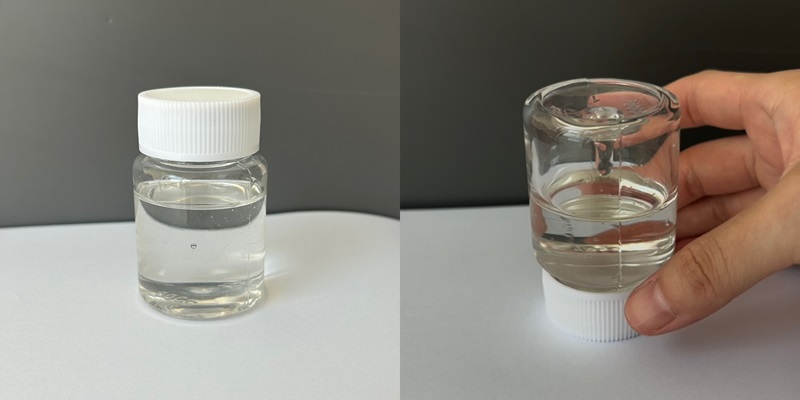

MXC-37 (2-(2-(dimethylamino)ethoxy)ethanol, CAS 1704-62-7) is a revolutionary amine catalyst that brings multiple breakthroughs to sandwich panel production:

- Emission-free, low-odor characteristics: solve the odor problem of traditional amine catalysts and improve the production environment

- High foaming activity: especially suitable for high-water content formulations to ensure full expansion of foam

- Dual application mode: can be used alone as a main catalyst or in combination with BDMAEE

- Wide compatibility: suitable for various polyester and polyether polyol systems

In the continuous production line of sandwich panels, MXC-37 can provide a stable reaction curve to ensure the uniformity and consistency of the foam core material, which is crucial to ensure the flatness and dimensional stability of the sandwich panels.

Technological breakthrough of MXC-15 (potassium octanoate solution)

MXC-15 (CAS 3164-85-0), as an efficient isocyanurate catalyst, provides key support for the production of PIR sandwich panels:

- Ultra-high conversion rate: promotes isocyanate trimerization and improves foam thermal stability

- Applicable to high viscosity formula: optimizes the fluidity and reaction uniformity of high solid content systems

- Economical and efficient: low addition amount can achieve excellent catalytic effect

- Professional matching PIR system: specially designed for polyisocyanurate sandwich panels

MXC-15 can significantly improve the fire resistance and dimensional stability of sandwich panels, so that they can still maintain excellent mechanical properties in high temperature environments.

The key role of catalysts in sandwich panel production

In the production process of polyurethane sandwich panels, the catalyst system directly affects the following core indicators:

1. Foam fluidity: ensure that the raw materials completely fill the cavity between the panels to avoid material shortage

2. Curing speed: match the speed requirements of the continuous production line to increase production capacity

3. Cell structure: affects the thermal conductivity and mechanical strength of the sandwich panel

4. Adhesion performance: determines the interface bonding strength between the core material and the panel

5. Dimensional stability: prevents panel deformation caused by foam shrinkage

Our technical team can provide the most optimized catalyst solution for different production lines and product requirements by precisely controlling the ratio of MXC-37 and MXC-15, helping customers achieve:

- Increase production line speed by 20-30%

- Increase product qualification rate to more than 98%

- Reduce energy consumption by 15-20%

- Significant annual comprehensive cost savings

Professional technical support and services

We provide all-round technical support for sandwich panel manufacturers:

- Formula optimization service: adjust the catalyst system according to the customer’s existing formula

- Process parameter guidance: provide optimal material temperature, mold temperature and other key parameter recommendations

- Production line commissioning: Technical personnel will guide production start-up on site

- Quality inspection support: Assist in establishing a sound quality control system

Get product information and technical consultation

We sincerely invite all sandwich panel manufacturers to learn more about the excellent performance of the MXC series catalysts. If you need detailed technical information or apply for free samples, please contact us through the following methods:

Email: info@mingxuchem.com

Website: www.mingxuchem.com

Choose our professional catalyst solutions to make your sandwich panel products stand out in the market!

Post time: May-08-2025